Category: Used Filling Monoblock, Used Isobaric Filling Monoblock

Code: QT 743

Year of Construction: 1998

Production (hour): 2.000 bph

Direction: Clockwise

Technical Info:

Used Filling Monoblock 16.20.1 Isobaric 2.000 bph:

Year: 1998

Speed: 2.000 bph

Direction: Clockwise

Model: Uniblock 16.20.1

Type of filling: isobaric

Rinser 16 clamps

• Fixed Nozzle

• Single treatment

Filler 20 valves

• Mechanical valves

Single head capper

• Natural Straight Cork

• Mushroom Cork

Microfiltration system included

PLC Siemens S7

Safety protections

Code: QT 743

Category:

Used Filling Monoblock, Used Isobaric Filling Monoblock

Code:

QT 743

Year of Construction:

1998

Production (hour):

2.000 bph

Direction:

Clockwise

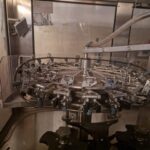

The Used Bertolaso Uniblock 16.20.1 isobaric monoblock, 2,000 bph is a complete and reliable solution for companies seeking consistent performance and high precision in small to medium capacity bottling lines. Manufactured in 1998, it offers a production speed of up to 2,000 bottles per hour and ensures operational stability throughout the entire work cycle.

The machine operates clockwise and combines three fundamental sections: rinser, filler, and capper. The rinser features 16 clamps and is equipped with a fixed nozzle with single treatment. This configuration ensures effective internal cleaning of the bottle before filling while maintaining low water consumption.

The isobaric filler integrates 20 mechanical valves. This solution provides precise control of the filling level and protects the integrity of the product, especially when working with delicate or lightly carbonated beverages. Thanks to its mechanical structure, the process remains stable and requires minimal adjustments, improving production continuity.

The single-head capper supports both straight corks and mushroom corks. This versatility makes it ideal for wineries, producers of still wines, sparkling wines, and other beverages requiring specific and reliable closures. Additionally, the system maintains precise cork positioning, ensuring excellent sealing over time.

The machine is equipped with a Siemens S7 PLC, which enhances operational management and simplifies line monitoring. Safety guards integrated throughout the structure reduce risks and ensure compliance with current safety standards. Moreover, the included microfiltration system helps maintain high product quality before the filling phase.

Overall, the Used Bertolaso 16.20.1 isobaric monoblock represents an efficient choice for companies seeking a reliable, versatile machine that is easy to integrate into existing lines. The combination of proven technologies and durable components guarantees continuous production and consistent quality over time.

Constructor: Bertolaso

Year of Construction: 1998

Production (hour): 2.000 bph

Direction: Clockwise

Technical Info:

Used Filling Monoblock 16.20.1 Isobaric 2.000 bph:

Year: 1998

Speed: 2.000 bph

Direction: Clockwise

Model: Uniblock 16.20.1

Type of filling: isobaric

Rinser 16 clamps

• Fixed Nozzle

• Single treatment

Filler 20 valves

• Mechanical valves

Single head capper

• Natural Straight Cork

• Mushroom Cork

Microfiltration system included

PLC Siemens S7

Safety protections

Code: QT 743

Request a quote for this machine

© 2025 Elitekno Bottling Solutions s.r.l. - Privacy Policy

Office: Via del Glicine, 9/A - 37051 Bovolone VR (Italy) - VAT: IT04498070236 - Share Capital: € 100.000,00