Category: Used Filling Monoblock, Used Gravity Filling Monoblock

Code: QT 715

Year of Construction: 2006

Production (hour): 5.500 bph

Direction: Clockwise

Technical Info:

Used Filling Monoblock MBF 20.25.4.3:

SYNCHROFILL 20-25-4-3 Model

Year: 2006

Direction of travel: clockwise

Speed: 5,500 BPH

Rinser with 20 clamps

Fixed nozzle

Single treatment

Electric height adjustment

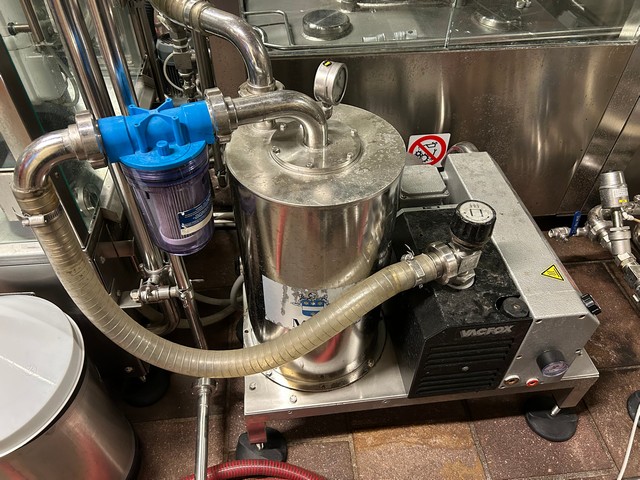

Water filtration system at rinser inlet

Filler with 25 valves

Light pressure

Electro-pneumatic filling valves

Electric tank height adjustment

Bottle level adjustment adjustable from operator panel

Vacuum system before filling

4-head corker for straight cork

Electric height adjustment

Vacuum system, inert gas injection and vacuum before corking

Cap elevator included

3-head aluminum screw corker for Stelvin cork (30×60)

Electric height adjustment

Pneumatic cap lift included

Speed adjustment via inverter

Touchscreen operator panel

PLC HAKKO ELETTRONICS

Code: QT 715

Category:

Used Filling Monoblock, Used Gravity Filling Monoblock

Code:

QT 715

Year of Construction:

2006

Production (hour):

5.500 bph

Direction:

Clockwise

Used MBF 20.25.4.3 Filling Monoblock, built in 2006 by the manufacturer MBF, is an integrated system designed to ensure an efficient filling process. This SYNCHROFILL 20-25-4-3 model has a production capacity of 5,500 bph and operates in a clockwise direction.

The monoblock is equipped with a rinser featuring 20 grippers and a fixed nozzle, allowing for a single treatment. The height adjustment is electric, while the water filtration system for the rinser ensures consistent quality.

The filler has 25 valves that operate with slight vacuum pressure and are equipped with electropneumatic filling valves. Additionally, the tank height adjustment is electric, and the bottle level can be adjusted via an operator panel.

An automatic washing and capping tray is included, as well as a vacuum system activated before filling. The corker has 4 heads for flat corks, and the height adjustment is electric. Moreover, there is a vacuum system, inert gas injection, and vacuum before corking.

The monoblock also includes a cork elevator and an aluminum screw capper with 3 heads for Stelvin caps (30×60), all equipped with electric height adjustments and a pneumatic cork elevator. The speed adjustment is managed through an inverter.

The operator panel is a touchscreen type, and the system is controlled by a HAKKO ELECTRONICS PLC.

Constructor: MBF

Year of Construction: 2006

Production (hour): 5.500 bph

Direction: Clockwise

Technical Info:

Used Filling Monoblock MBF 20.25.4.3:

SYNCHROFILL 20-25-4-3 Model

Year: 2006

Direction of travel: clockwise

Speed: 5,500 BPH

Rinser with 20 clamps

Fixed nozzle

Single treatment

Electric height adjustment

Water filtration system at rinser inlet

Filler with 25 valves

Light pressure

Electro-pneumatic filling valves

Electric tank height adjustment

Bottle level adjustment adjustable from operator panel

Vacuum system before filling

4-head corker for straight cork

Electric height adjustment

Vacuum system, inert gas injection and vacuum before corking

Cap elevator included

3-head aluminum screw corker for Stelvin cork (30×60)

Electric height adjustment

Pneumatic cap lift included

Speed adjustment via inverter

Touchscreen operator panel

PLC HAKKO ELETTRONICS

Code: QT 715

Request a quote for this machine

© 2026 Elitekno Bottling Solutions s.r.l. - Privacy Policy

Office: Via del Glicine, 9/A - 37051 Bovolone VR (Italy) - VAT: IT04498070236 - Share Capital: € 100.000,00