Category: Used Filling Monoblock, Used Gravity Filling Monoblock

Code: QT 741

Year of Construction: 2002

Production (hour): 4.200 bph

Direction: Clockwise

Technical Info:

Used Filling Monoblock Envastronic 20.3:

Model: L2CT3ArolCC

Year: 2002

Speed: max 4.200 bph

Direction of rotation: clockwise

Filler 20 valves

– Tank height adjustment is electric

– Type of filling: gravity

– Valve: automatic, mechanical-pneumatic, operated by level photocells

– Vacuum system before filling

One Arol Capper with 3 heads

– height adjustment of the Arol corking turret is electric

– Type of workable caps: natural straight cork

– Vacuum system before capping

– Including cap elevator of 2004 Costral, mechanically operated with a connecting rod and with a capacity of approximately 6,000 corks

Safety protections

Machine layout

Code: QT 741

Category:

Used Filling Monoblock, Used Gravity Filling Monoblock

Code:

QT 741

Year of Construction:

2002

Production (hour):

4.200 bph

Direction:

Clockwise

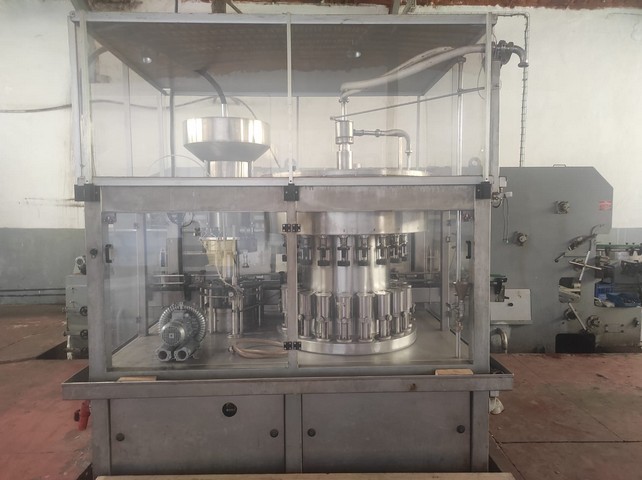

Used ENVASTRONIC 20.3 Filling Monoblock, built in 2002, designed for a production rate reaching up to 4,200 bph. This system operates clockwise and is equipped with a 20-valve filler. The tank height adjustment is electric, while the filling type is gravity. The valve is automatic, mechanical-pneumatic, and operated by level photocells. There is also a vacuum system before filling.

The capper is an Arol with 3 heads, also equipped with electric height adjustment of the capping turret. This capper can handle straight cork type caps and includes a vacuum system before capping. The monoblock comes with a 2004 cap elevator, model Costral.

The machine is equipped with safety guards and features a layout designed to optimize operational efficiency.

Constructor: ENVASTRONIC

Year of Construction: 2002

Production (hour): 4.200 bph

Direction: Clockwise

Technical Info:

Used Filling Monoblock Envastronic 20.3:

Model: L2CT3ArolCC

Year: 2002

Speed: max 4.200 bph

Direction of rotation: clockwise

Filler 20 valves

– Tank height adjustment is electric

– Type of filling: gravity

– Valve: automatic, mechanical-pneumatic, operated by level photocells

– Vacuum system before filling

One Arol Capper with 3 heads

– height adjustment of the Arol corking turret is electric

– Type of workable caps: natural straight cork

– Vacuum system before capping

– Including cap elevator of 2004 Costral, mechanically operated with a connecting rod and with a capacity of approximately 6,000 corks

Safety protections

Machine layout

Code: QT 741

Request a quote for this machine

© 2026 Elitekno Bottling Solutions s.r.l. - Privacy Policy

Office: Via del Glicine, 9/A - 37051 Bovolone VR (Italy) - VAT: IT04498070236 - Share Capital: € 100.000,00