Category: Used Complete Bottling Line , Used Bottling Line – PET

Code: NP 647

Year of Construction: 2010

Production (hour): 24.000 bph

Direction: n/a

Technical Info:

Used Complete Krones PET Bottling Line 24.000 bph

Year of Manufacture: 2010

Suitable for: Carbonated Drinks

Current Product: Apple Juice with Water and CO2

Container Sizes: PET 0.5 L – PET 1.0 L – PET 1.5 L

Neck Format: PCO 1810 – 28 mm PSO 28 mm – 1810 – 1881 (Short Neck)

Capacity:

24,000 BPH for 0.5 L

18,000 BPH for 1.5 L

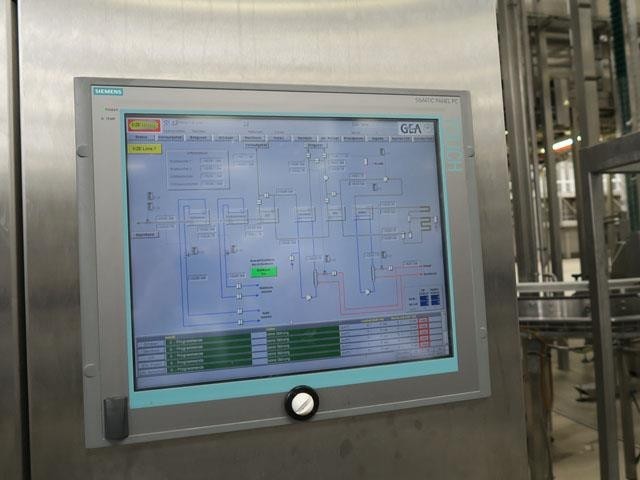

Control PLCs: Siemens Simatic S7-series

Working Time: Approximately 40,000 hours

Krones VarioClean F AUT: Fully Automatic CIP System, 4 x 5000 liters, 30 m³/h

GEA TDS Processing Plant: Includes flash pasteurizer, mixer, carbonator, degasser, and tanks

Preform Kipper and Feeding Conveyors:

Preform Feeding System: Krones Contifeed RS

Preform Cleaning Unit: Prejet Linear

Gassner Cap Feeding System: Includes cap rinsing and sterilization

Blow Moulder: Krones Contiform S12M

Ultra Clean Krones Volumetric Filler: Type Volumetric VODM-PET and Capper

Ultra Clean Krones Vario Dos: Filler block cleaning system

Date Coder: Domino DDC 3 (laser)

Filling Level Inspector: Krones Checkmat

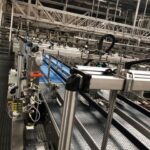

Bottle Conveyors: SYNCO S

Krones Flowliner: Bottle leaking tester

Labelling Machine: Krones Contiroll OPP 720-15, double roll feed label with hot glue

Label Inspector: Krones Checkmat 731 EM

Krones (Kettner) Variopac TFS 30 (2003)

Packet Conveyors: Krones Multico S

Handle Applicator: Twin Pack

Pack Coding: Leisinger Jet 3 (ink)

Palletizer: Krones Robopox Modulpal (Year 2016)

Code: NP 647

Category:

Used Complete Bottling Line , Used Bottling Line - PET

Code:

NP 647

Year of Construction:

2010

Production (hour):

24.000 bph

Direction:

n/a

Used Complete Krones PET Bottling Line 24.000 bph from the manufacturer Krones, constructed in 2010, is designed for the production of carbonated drinks. The line has an hourly production capacity of 24,000 bph for 0.5 L containers, reducing to 18,000 bph for 1.5 L containers.

This bottling line is suitable for various container sizes, including PET 0.5 L, PET 1.0 L, and PET 1.5 L. It accommodates neck formats such as PCO 1810, 28 mm PSO 28 mm, 1810, and 1881 (Short Neck). With approximately 40,000 hours of working time logged, this equipment features Siemens Simatic S7-series PLCs for control.

Key components of the line include the Krones VarioClean F AUT, which is a fully automatic CIP system with a capacity of 4 x 5000 liters and a flow rate of 30 m³/h. The GEA TDS Processing Plant is equipped with essential features such as a flash pasteurizer, mixer, carbonator, degasser, and various tanks for optimal processing.

The Krones Contifeed RS serves as the preform feeding system, complemented by the Prejet Linear cleaning unit. The Gassner Cap Feeding System includes rinsing and sterilization processes to ensure cap integrity. The blow moulder is a Krones Contiform S12M, which prepares the bottles for filling.

Filling is handled by the Ultra Clean Krones Volumetric Filler (Type Volumetric VODM-PET) along with the Capper. The taping and cleaning is managed by the Ultra Clean Krones Vario Dos filler block cleaning system. Additionally, a Domino DDC 3 (laser) provides date coding for products, and the filling level is monitored by the Krones Checkmat.

The system includes SYNCO S bottle conveyors and a Krones Flowliner for bottle leakage testing. Labelling is executed via the Krones Contiroll OPP 720-15, which utilizes double roll feed labels applied with hot glue. A Krones Checkmat 731 EM monitors labels for accuracy.

Other features include the Krones (Kettner) Variopac TFS 30 for packaging, a Krones Multico S for packet conveyors, and a Twin Pack handle applicator. Pack coding is provided by the Leisinger Jet 3 (ink) unit, while the Krones Robopox Modulpal (Year 2016) operates as the palletizer for efficient handling and processing of finished products.

Constructor: Krones

Year of Construction: 2010

Production (hour): 24.000 bph

Direction: n/a

Technical Info:

Used Complete Krones PET Bottling Line 24.000 bph

Year of Manufacture: 2010

Suitable for: Carbonated Drinks

Current Product: Apple Juice with Water and CO2

Container Sizes: PET 0.5 L – PET 1.0 L – PET 1.5 L

Neck Format: PCO 1810 – 28 mm PSO 28 mm – 1810 – 1881 (Short Neck)

Capacity:

24,000 BPH for 0.5 L

18,000 BPH for 1.5 L

Control PLCs: Siemens Simatic S7-series

Working Time: Approximately 40,000 hours

Krones VarioClean F AUT: Fully Automatic CIP System, 4 x 5000 liters, 30 m³/h

GEA TDS Processing Plant: Includes flash pasteurizer, mixer, carbonator, degasser, and tanks

Preform Kipper and Feeding Conveyors:

Preform Feeding System: Krones Contifeed RS

Preform Cleaning Unit: Prejet Linear

Gassner Cap Feeding System: Includes cap rinsing and sterilization

Blow Moulder: Krones Contiform S12M

Ultra Clean Krones Volumetric Filler: Type Volumetric VODM-PET and Capper

Ultra Clean Krones Vario Dos: Filler block cleaning system

Date Coder: Domino DDC 3 (laser)

Filling Level Inspector: Krones Checkmat

Bottle Conveyors: SYNCO S

Krones Flowliner: Bottle leaking tester

Labelling Machine: Krones Contiroll OPP 720-15, double roll feed label with hot glue

Label Inspector: Krones Checkmat 731 EM

Krones (Kettner) Variopac TFS 30 (2003)

Packet Conveyors: Krones Multico S

Handle Applicator: Twin Pack

Pack Coding: Leisinger Jet 3 (ink)

Palletizer: Krones Robopox Modulpal (Year 2016)

Code: NP 647

Request a quote for this machine

© 2026 Elitekno Bottling Solutions s.r.l. - Privacy Policy

Office: Via del Glicine, 9/A - 37051 Bovolone VR (Italy) - VAT: IT04498070236 - Share Capital: € 100.000,00