Category: Used Complete Bottling Line , Used Bottling Line – PET

Code: NP 613

Year of Construction: 2015

Production (hour): 15.000 bph

Direction: n/a

Technical Info:

Speed: 15.000 Bph on 1.5l

Year: 2015

Worked hours: 14.000

Formats: 0.5 LT and 1.5 LT

COMBI-BLOCK

Blow moulding machine SIDEL

Model: SBO 8

Preform tipper

Preform orientation

Chiller

Compressor

Measures: PO 28 – 1881

Rinser

Isobaric filler

Capper AROL 10 teste

Model: EURO PK

Type of cap: screw cap and sports cap

FT-SYSTEM INSPECTOR

Level inspection

Cap presence check

Defect ejector

Labeller SIDEL ROLLQUATTRO

Number of heads: 18

Type: Rollfed

MARKER

Shrink wrapper SIDEL

4 row entrance

At film launch

GEBO-CERMEX PALLETIZER

Model: PAL-KOMBI

Double entrance belt

Type: push

pallet warehouse

ROBOPACK PALLET WRAPPER

Model: HELIX 1

PALLET LABELING MACHINE

Safety protections

Code: NP 613

Category:

Used Complete Bottling Line , Used Bottling Line - PET

Code:

NP 613

Year of Construction:

2015

Production (hour):

15.000 bph

Direction:

n/a

The used PET bottling line 15,000 bph is an advanced industrial system designed to meet high-capacity production needs in the bottled beverage sector. With a maximum speed of approximately 15,000 bottles per hour (bph) for the 1.5-liter format and the ability to handle 0.5-liter bottles as well, this line stands out for its efficiency and reliability.

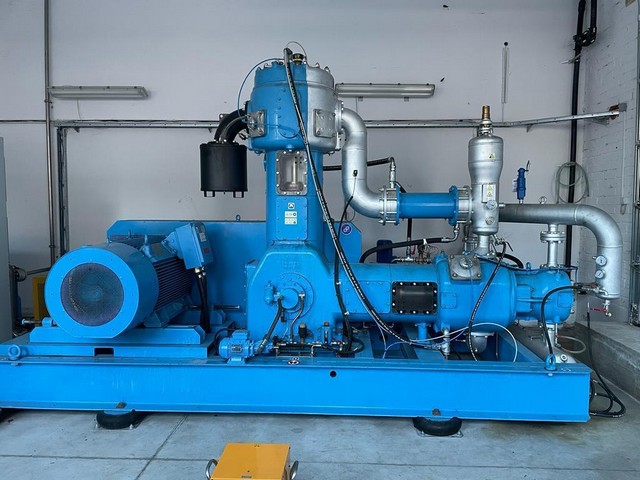

The heart of the plant is the combi-block which includes the SIDEL blower model SBO 8, accompanied by a preform inverter and orientator, as well as a chiller and compressor to ensure optimal production conditions. The line features a rinser and an isobaric filler that guarantee precise filling and product quality maintenance.

The AROL 10-head capping machine, model EURO PK, is versatile and suitable for both screw caps and sport caps, while the FT-System inspector carefully checks the fill level, cap presence, and rejects any defects, thus ensuring a final product that meets the highest quality standards.

For labeling, there is the SIDEL Rollquattro labeler with 18 heads, roll-fed type, accompanied by a marker for product identification. Packaging is handled by the SIDEL shrink-wrapper with 4-lane entry and film-throwing system, preparing products for palletizing.

The GEBO-CERMEX palletizer model PAL-KOMBI, equipped with a double inlet conveyor and push system, manages pallet loading and unloading, supported by a pallet warehouse and a Robopack HELIX 1 stretch-wrapper. The plant is also equipped with a pallet labeler and safety guards that ensure operational safety.

In summary, this used PET bottling line 15,000 bph offers a complete, reliable, and highly efficient solution for companies looking to optimize production in the plastic beverage sector.

Constructor: Sidel

Year of Construction: 2015

Production (hour): 15.000 bph

Direction: n/a

Technical Info:

Speed: 15.000 Bph on 1.5l

Year: 2015

Worked hours: 14.000

Formats: 0.5 LT and 1.5 LT

COMBI-BLOCK

Blow moulding machine SIDEL

Model: SBO 8

Preform tipper

Preform orientation

Chiller

Compressor

Measures: PO 28 – 1881

Rinser

Isobaric filler

Capper AROL 10 teste

Model: EURO PK

Type of cap: screw cap and sports cap

FT-SYSTEM INSPECTOR

Level inspection

Cap presence check

Defect ejector

Labeller SIDEL ROLLQUATTRO

Number of heads: 18

Type: Rollfed

MARKER

Shrink wrapper SIDEL

4 row entrance

At film launch

GEBO-CERMEX PALLETIZER

Model: PAL-KOMBI

Double entrance belt

Type: push

pallet warehouse

ROBOPACK PALLET WRAPPER

Model: HELIX 1

PALLET LABELING MACHINE

Safety protections

Code: NP 613

Request a quote for this machine

© 2026 Elitekno Bottling Solutions s.r.l. - Privacy Policy

Office: Via del Glicine, 9/A - 37051 Bovolone VR (Italy) - VAT: IT04498070236 - Share Capital: € 100.000,00